-

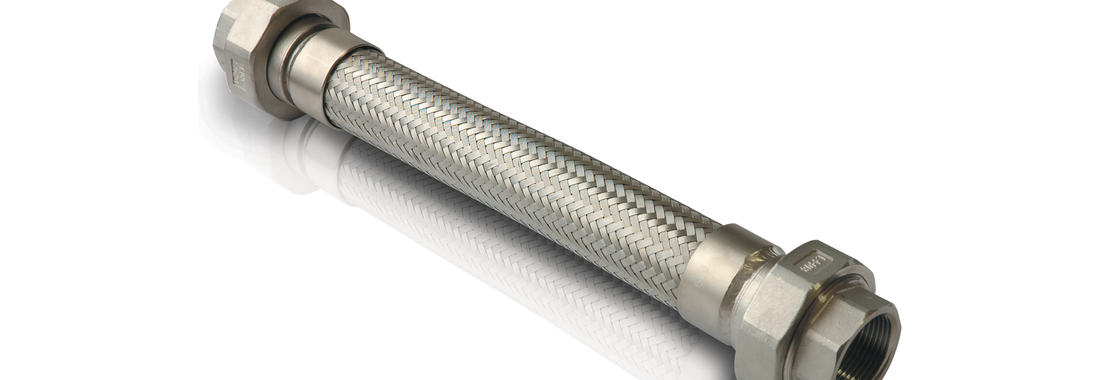

CORRUGATED HOSES

-

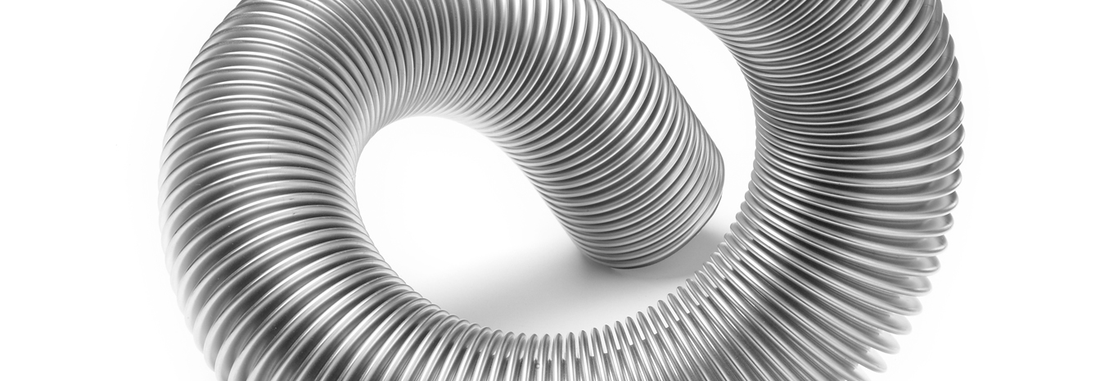

STRIPWOUND HOSES

Basically, there are two different types of metal hoses, corrugated hoses and stripwound hoses.

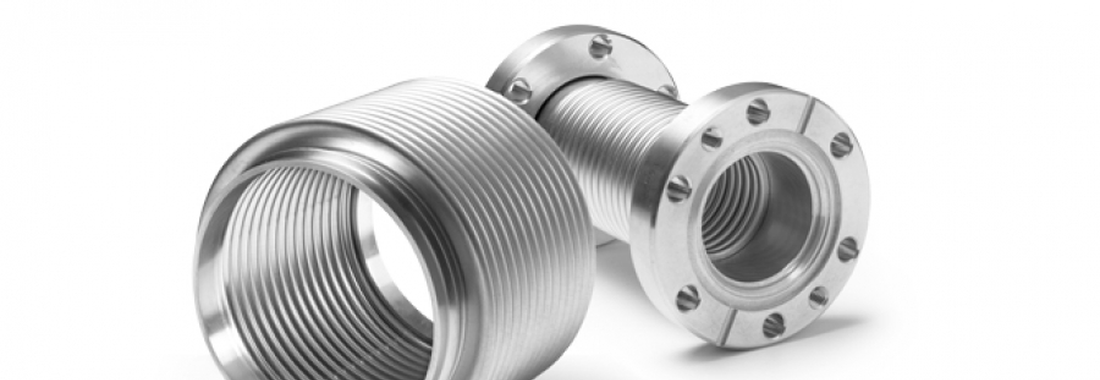

Corrugated hoses are pressure-tight, thin-walled elements with a corrugated structure. They are typically used to convey pressurised liquids or gases, or as flexible connecting elements to absorb movement, thermal expansion or vibration.

Stripwound hoses are manufactured from a profiled strip that is coiled spirally so that it interlocks. They are typically used as flexible, heat and ageing resistant elements in exhaust gas technology, as protective conduits for electric cables or light conductors, or as extraction and delivery hoses.

Metal hoses provide a wide range of solutions in various fields of application, e.g.

- absorb vibrations, misalignment or thermal expansion

- facilitate repetitive machine movements

- avoid cracking of piping due to stress fatigue

- prevent leakages at joints, gaskets or flanges due to undesirable tensions

Please see a selection of relevant standards for metal hoses here.

-

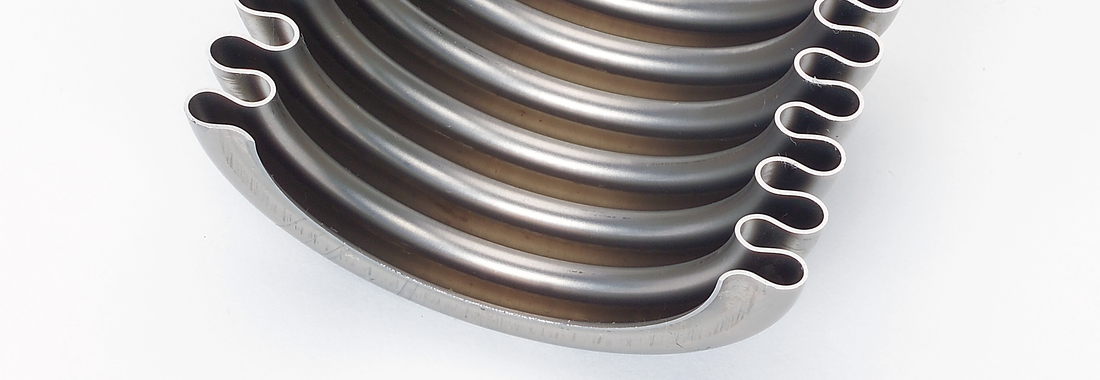

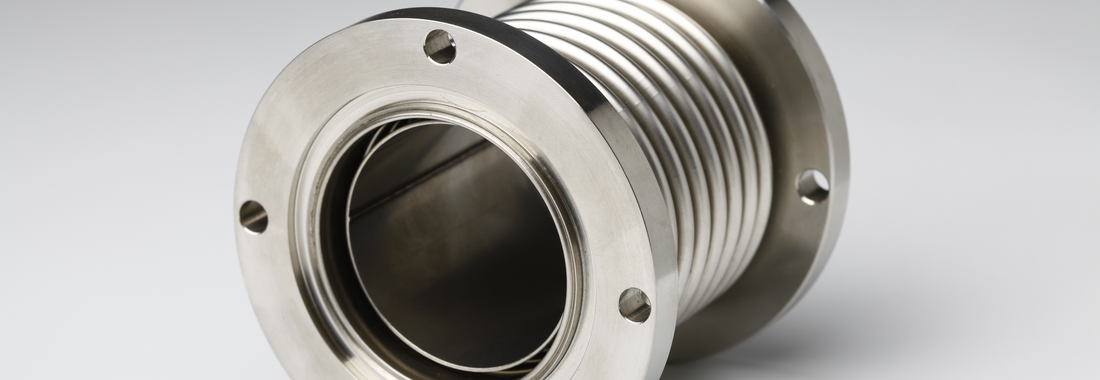

SINGLE-PLY BELLOWS

-

MULTI-PLY BELLOWS

Metal bellows are produced from ductile metallic materials. The basic element, which is a thin-walled cylindrical tube, is formed into corrugations using hydraulic or mechanical pressure. Depending on the main requirements, which are pressure and deflection, the bellows can be either single plied (low pressure and vacuum applications) or consist of a multiple ply structure with up to eight individual layers (high pressure applications). The corrugation geometry is variable too and depends on the production quantity, the process used as well as on the application.

Metal bellows

- are extremely flexible,

- allow considerable axial, lateral or angular movements,

- have a long life expectancy,

- do not need any maintenance,

- are resistant to pressure and to temperature, and

- are vacuum-tight.

-

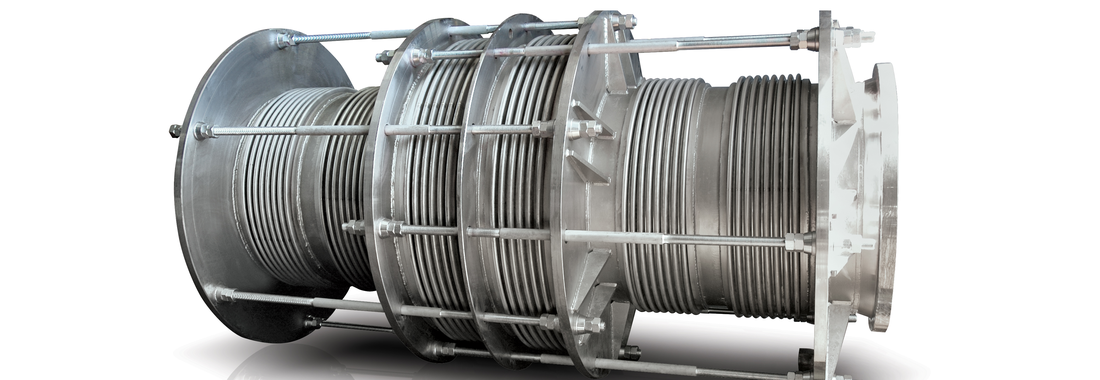

ANGULAR ROTATION EXPANSION JOINTS

-

AXIAL EXPANSION JOINTS

-

LATERAL EXPANSION JOINTS

-

UNIVERSAL EXPANSION JOINTS

Pipelines are usually constructed at ambient temperature and operated at elevated temperature. Due to the thermal expansion of nearly all metals, this causes a variation in the length of individual sections. As pipelines are normally anchored on at least two connection points, any variation in length (thermal strain) will result in enhanced forces and moments at these terminal points.

The inherent flexibility of a straight pipeline is usually not sufficient to compensate the pipe expansion (natural compensation). Thus, either large U-shaped structures of the pipeline or the use of expansion joints is necessary to compensate the thermal strains. In that way, expansion joints help to limit forces and moments on nozzles of compressors, turbines, vessels and other plant components. Specially designed expansion joints can also damp mechanical vibrations of pumps, compressors, turbines and motors.

The central component of each expansion joint is the metal bellows that, due to its shape and thin walls, combines flexibility, tightness and pressure resistance.

Please see a selection of relevant standards for expansion joints here.